Slowpoke is everyone’s favorite derpy pink gen 1 Pokemon. Download the free pattern and make your own Slowpoke hat to wear on those days you’re feeling extra listless or carefree. Hopefully you won’t procrastinate finishing it as badly as I did.

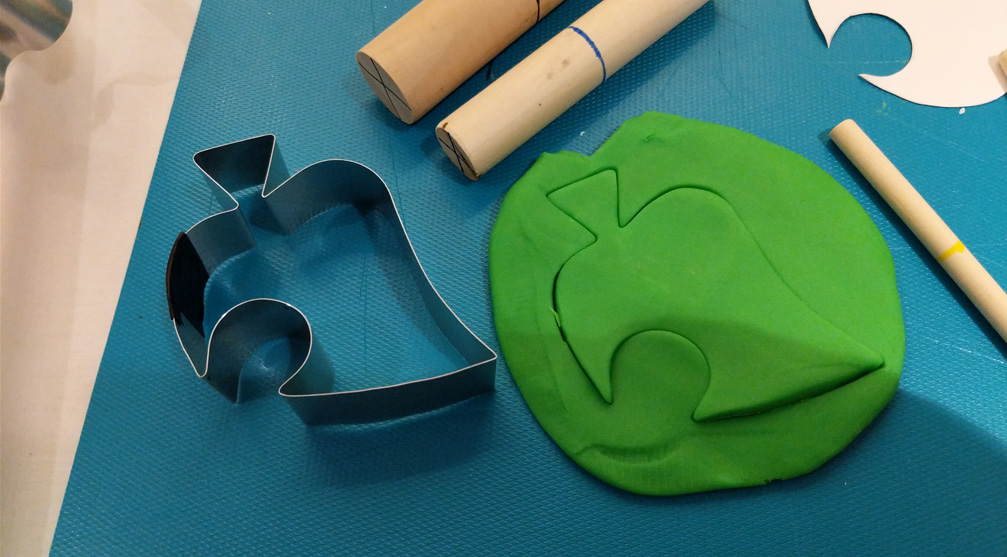

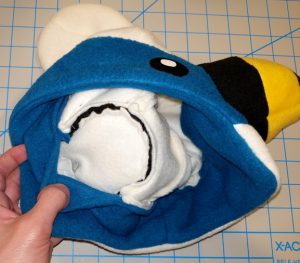

Turtwig Fleece Hat

Turtwig is the pale-green, yellow, and brown turtle with a sapling growing out of his head. He’s the Pokemon gen 4 grass starter. I designed this Trutwig fleece hat for Pokemon Go’s September 2019 Community Day. If you’d like to make your own, check out the resources below.

Vintage Radio and Communications Museum

Last week my friends asked if I wanted to go to the “HAM swap” and then check out “the radio museum”. To be honest I wasn’t that excited about the prospect. HAM swaps or fleas are where you go to spend too much money on Pentium II desktop computers and burned-in monitors. And I don’t need the extra junk. I also haven’t exercised my HAM license in the last 15-ish years, so I didn’t really care about looking at a bunch of old radios either.

Fortunately, my imagination proved to be wrong on this occasion. The swap meet took place at the Vintage Radio and Communications Museum, located in Windsor, CT. It’s just a little bit out from the main airport, Bradley International Airport. The museum itself is in a nondescript brick-faced building off the beaten path. It would be easy to mistake for a small warehouse, machine shop, or old line engineering firm. That’s perhaps fitting for what’s contained within. The museum was hosting the swap, and since we’re into the winter months now, the swap took place inside, with folding tables of various contents-for-sale mixed in between the aisles of exhibits. Initially it was hard to tell that these weren’t all part of the same big collection.

I didn’t intend to spend any money, which I stuck to. As I said in our planning conversation, “I don’t plan on buying shit”. There’s at least 3 ways to interpret that statement, and they’re all correct. I was just there to look around.

As an aside, for the past couple years I’ve been attending MAGFest (as I sometimes reference in this blog), and one of their areas is the computer museum. It’s a lovely space decked out with old PCs, Macs, and beyond, ranging from the ancient to the not-so-distant past, mostly loaded up to play equally old games. You can also find some other odd bits of history and technology mixed in to enhance that museum quality feel. If you could imagine expanding the MAG museum’s to include more A/V and telecom history, then stretch that back to 1890, you end up with this place.

The Vintage Radio and Communications Museum, or “the radio museum” does indeed have many radios on display, going back as far as those devices have existed. But they also have some other neat, old tech on display. They have displays of telegraphs, original (and later) telephones, phonographs, early film projectors, radio transmitters and receivers of all ages, telephone switching equipment, general electronics, the evolution of Hi-Fi and stereo, televisions, video recording and broadcast, and an assortment of old computers that would feel right at home at MAGFest.

Everything in the museum is grouped approximately by the decade it was developed in, with large signs hanging from the ceiling denoting this timeline. By the time you reach the end of the timeline, somewhere in the 1980s, you might even recognize some stuff you grew up with, or heavens even still own. Were YOU cool enough to own a Sony Watchman?

The museum is run by a volunteer organization, and on any given day that they’re open, numerous volunteers are prowling around to give guided tours or just explain a piece of technology. One of the really neat things about this museum is almost nothing is roped off or behind glass. All the equipment is on display and generally there to see and touch. And a lot of this equipment, some of it over 100 years old, is in working condition and the volunteers will happily do a live demo for you. One volunteer approached us while we were looking at some old phonograph console cabinets, which look like a turntable on top of a large wooden speaker cabinet. The speaker however, though hidden from view, is actually a large horn, like the ones you imagine when you think of old-timey phonographs. After describing a bit of this cabinet to us, he started playing a shellac record from 1925. What really struck me about this demo is that there is no electricity involved. You give the handle on the side a few cranks which is enough to spin the record through the duration of the song. The enormous phonograph horn hidden behind the cloth fabric of the cabinet is enough to amplify whatever the needle picks up off the record with plenty of volume. Maybe the fact that I couldn’t see the horn and it looks like it should be an electric speaker is what gave it that touch of witchcraft magic. By the way, Shazam had no trouble recognizing that record (but I forgot what it was already, sorry).

Another demo we were given was on a 1920s tube raido receiver, which can receive AM radio bands. AM radio has apparently gone unchanged, as the volunteer was able to tune the radio to a local station, which was broadcasting a story on the death of President George H. W. Bush. It was bizarrely fitting, perhaps eerie even, to be listening to this broadcast on the same radio that might have been informing someone about the death of President Warren G. Harding. That’s pretty incredible.

Not everything needs to be done by the volunteers; some of the exhibits can be played with directly as well. One of the exhibits, in the “1940s” section, is a huge multi-rack of AT&T telephone switching equipment. It’s more of a solid wall of wires, eletronics, and egad knows what. Did you know that when the North American Numbering Plan was developed, area codes were distributed such that the busiest metro areas (like New York) would have the lowest digits in their area code, which would require the fewest number of “clicks” on the switching equipment, and actually be faster to connect than numbers in area codes with higher digits? New York has area code 202 (among many more today), which was the shortest, fastest code that could be assigned under the plan. This was life working with mechanical constraints! Back to the museum display though, they have one of those central office “mechanical switches” on display, next to a rotary phone dial that visitors can use. Each number on the rotary dial creates the same number of pulses (except 0, which is located after 9 and has 10 pulses). Each pulse causes a mechanical movement in the switch, which you can see. And two “digits” must be entered into the switch to complete a connection. I have no idea how any of that really works, but it looks complicated as hell and someone had to engineer those systems and all that hardware.

Like the phone rack, a 1970s display includes a collection of VHS broadcasting equipment that has clearly come from a local broadcasting station that was decommissioning pretty much everything. The interesting bit about this display is the equipment looked shiny and new, like it had only recently been pulled out of service. And indeed, there were visible service tags for maintenance/replacements for the years 2005 and 2007. I suspect that this equipment was in active use until 2010, when the venerable analog NTSC broadcasting in the United States was shut down.

There’s all kinds of strange and interesting things threaded throughout the larger themes of the museum. Artifacts and notes are strung up just about everywhere like the walls of a 99 restaurant, except it’s all real. Did you know that in the 1930s, a company started selling refrigerators with a built-in radio? The radio took up the entire top section of the refrigerator, which you would otherwise have assumed was the freezer. If that sounds crazy, they sold 4 million of them. It turns out that such a combination was a big hit for lonely housewives working in the kitchen all day.

If you’re in Connecticut near Bradley Airport and have some extra time, it’s worth taking a visit. General admission is $10, although if you go on a swap meet day they might not charge you. We didn’t have to pay today. We took about 2 hours to wander around and look at things. We didn’t have a full tour, but those are offered and would probably be very interesting with all the extra knowledge and backstory that the volunteers can provide.

MAGLabs Workshop Review

Whew, I’ve been so wrapped up with other projects I forgot to recap the cookie cutter workshop I ran at MAGLabs in September. This was the first workshop I’ve run, and it was an absolute joy to come share this fun little craft project with others. Thank you to everyone who attended!

I was quite happy with how everything went, and the creativity of some attendees who created their own designs and patterns – then built them! I also received some good feedback on improvements I could make if I run this workshop again in the future.

And speaking of future workshops, here’s a soft announcement that the cookie cutter workshop is coming to Super MAGFest this year! I’m super excited to bring this to the big event. The workshop will be running on Friday, January 4th, at 7:00 PM in the maker space (formerly the Forge).

I haven’t posted any of the instructional content I mentioned yet, but I’d like to do so before the workshop runs, so that the resources will be available online for everyone. In the meantime, here’s a link to the instructional sheets I handed out as part of the workshop, which includes a collection of pre-made patterns and some additional information like a pattern key and a bend radius guide:

Pattern sheets:

MAGLabs Workshop

If you’re attending MAGLabs this year, I’m running a maker workshop on Sunday, Sep. 9th at 12:00 PM for building your own metal cookie cutters. I’ll be providing all of the tools and materials in addition to instruction. All you have to do is show up!

I made my first set of video-game themed cutters on a whim in 2011 for a secret Santa project. They’re quite easy to make with minimal tools and materials, so I’m excited to share this in a workshop setting. I’ll post some instructional content and patterns after the event.

Magnet Shoes

I’ve been continuing to make progress on a Scyther cosplay, and I’ve been doing some work on the feet. If you’re a bit rusty on your Pokemon designs, Scyther has some pretty large feet attached to his little stick legs. Since I’m designing my costume to be faithful to the Pokemon X/Y model that I’m using as a reference, that means making feet that are also much larger than a normal shoe or boot.

The idea is that the foot is built as a shell with some normal, wearable footwear embedded inside. Ideally, I’d like to be able to wear some normal shoes which would provide very secure attachment and at least be moderately comfortable. But if I glue shoes to the inside of the shell, I can’t really get access to lace and unlace them. So what to do?

Early on, I got the idea to try attaching the shoes to the inside with magnets. Specifically those strong rare-earth neodymium magnets that feel impossible to separate when two get stuck together. The idea is pretty simple: take a relatively flat shoe, embed several magnets in sections that are normally in contact with the ground, and embed another set of magnets in the same location in the base of the foam Scyther foot. Then you can lace up your shoes, stick your foot inside, and the magnets should engage. Now the rest of the foot will move when you do.

I made a first attempt using some small 10mm magnets, which you can see in this photo.

Unfortunately the attractive force wasn’t that strong. Any resistance on the foam bottom would cause the shoe to disengage, as well as any flex in the foot from walking. Flex is something I did consider, but thought would be minimal since wearing these feet will be like wearing flippers. Still, there’s enough to be a problem.

I did a second test with some larger 20mm magnets. That should work out to 4x more attractive force overall. It was an improvement, but in a test walk the foam bottoms were still detaching all the time. Maybe I could keep adding magnets and find a break point where the attachment is reliable enough, but I think I’m ready to lay this idea to rest.

Mareep hat

If you haven’t been up on Pokemon Go for the last several months, Niantic introduced a monthly recurring “community day” where a single Pokemon takes over the map for 3 hours. So far we’ve had a community day for Pikachu, Dratini, Bulbasaur, and most recently Mareep. Starting with Dratini, I made a hat themed for each community day.

This brings us to today’s hat: Mareep! I’ve only designed a handful of hats, but this was by far the most complicated one to create, both in terms of pattern and construction. If you’re up for a challenge though, I’m providing my patterns for free to anyone who wants them. The patterns are split across two files: a basic pattern that I use as a foundation for most of my hats, and a separate pattern with all of the Mareep-specific parts. Check the following links:

- Basic Pattern – 23 inch, 6 panels, ear flaps (PDF) | (Inkscape SVG)

- Mareep Pattern (PDF) | (Inkscape SVG)

In the SVG files, each page is stored in a separate layer.

Note, the small marks covering the edges of some patterns are registration marks. After you trace and cut your fabric, go back and copy the registration marks to your seam allowance to help align fabric joins.

Materials

Fleece

I use Anti-Pill fleece for my hats, which can be found at Joanne’s or elsewhere. This stuff goes on sale for 40-70% off at Joanne’s pretty frequently, so that’s something to keep an eye out for.

The Mareep hat uses 4 colors: black, daffodil, ivory, and blue (I think I used mykonos blue, but availability might be spotty). You’ll need 1/4 – 1/2 yard of the ivory, and 1/4 yard or less for the other colors.

Polyfill

StripFlock

This is a brand name for fuzzy heat-transfer vinyl sheets. You’ll need black and white to make Mareep’s eyes.

Construction

The Mareep hat can be broken down into the basic parts: headband, crown, ear cones, and swirl.

Headband

The headband is constructed from one headband piece in the basic pattern, and one each of the front / back headband pieces in the Mareep pattern. The basic pattern should be sewn together at the ends to form a loop. The front and back patterns should be sewn together at the curved ends where they fit together, also forming a loop. The front and back parts should be using different fabric colors.

Place one loop inside the other (“bad” side of fleece facing out on each side) and sew them together along the bottom edge. Fold right-side-out.

Swirl

Sew the smaller swirl part to the larger swirl part where they fit together as indicated by the registration marks on those pieces. Repeat for the flipped pieces for the back side. With both sides created, put them together bad side out, and sew the edges together everywhere except for the wide “top”, which is where the swirl will attach to the crown. You’ll need to do this in two steps, because the fabric overlaps back onto itself. Turn inside out and set aside.

Crown

The crown is constructed from two of the basic pattern triangles, and two each of the Mareep pattern triangles. Sew together the 3 front pieces and 3 back pieces as separate halves. Remember that the circle “notches” should be on the ends of each half. Take the swirl you set aside, and place it between the two halves of the crown. When turned inside-out, the swirl should be pointing into the hat.

Sew the halves together, which also sews the swirl in place. Try to pin it securely; 4-6 layers of fleece is a lot of bulk and the swirl will easily slip under the presser foot of your machine.

Ear Cones

Sew cone parts 1, 2, and 3 together to create a single striped piece. Use the registration marks to help you line up the edges. Once combined, sew the side edges together to complete the cone shape, then turn inside-out. Repeat for a second cone.

Attaching the ear cones to the headband

Unfold the headband so that you have a wide ring of fabric with circular notches cut out on one side. Pin the cones to these cut-out areas (the registration marks are REALLY important here to make sure the cones will attach evenly to all parts of the hat). Additionally, take your cone bottom circle pieces, and pin half of them to the inside of the cone. You should have 3 layers of fabric forming a semi-circle: the outer headband, the cone, and the cone bottom. Carefully sew these layers together. Fold the headband right-side-out again.

If done correctly, the bottom half of each cone will be secured to the headband, with the bottom half of the cone bottom also secured in place on the inside. The inside layer of the headband overlaps that circle, but is not directly attached to it.

Attaching the headband to the crown

You’ll essentially repeat the previous step, but attaching the cones to the crown part instead. Working on the inside of the hat, start by pinning each cone in place, and then pin the remaining crown areas to the headband. Once everything is secure, do a test fit (careful not to poke yourself!). If the hat sits too high or low, you can unpin it and adjust the slack in your seam allowance to make up the difference.

At this point the hat is quite unwieldy to manage, so expect to sew the cone parts and headband parts separately.

Stuffing the cones

If you assembled everything correctly, then the interior side of the headband is not attached to anything over the cones. Pull this back with your hand, and use scissors to cut a small opening in the cone bottom pieces. Use these holes to stuff the cones with poly-fill. Add enough poly-fill to get a good self-supporting shape, but don’t overfill. Too much fill will create extra pressure on the side of your head when wearing the hat. The holes you cut will be hidden by the headband and you can access them later to adjust the fill if needed.

Adding Eyes

Although you can use a variety of materials for this, I use strip flock in the form of iron-on vinyl transfers. Cut out the eye-shaped pieces from your flock sheet. Hang your hat from the end of an ironing board, with the area you’ll be adding the eye sitting on top of the board. Position your eye piece, cover in a thin cloth or Teflon sheet, then press and hold a hot iron over the area for about 15 seconds. I suggest a medium-high setting (e.g. wool) and to iron as small an area as possible. The heat will slightly damage the fleece, so do not over-iron. The iron-on flock can be stacked, but each layer needs to be ironed separately.

Simplified Construction

To create a simplified version of this hat, instead construct a blue and ivory version of the basic hat pattern with the swirl stitched into the top as described (or not, for an even simpler design). After the hat is completed, build your ear cones, stuff them with some poly-fill, and hand sew them onto the sides of the hat. Tuck the edges in and use a basic ladder stitch for a clean attachment. This won’t be quite as secure as the machine stitch, and you will not be able to adjust the fill levels without ripping part of your seam.

Pokemon hats (and friends)

For the last 15 months, when the weather has been cooler, I’ve been wearing fleece Pokemon hats almost religiously. They’re nice to wear indoors or outdoors. They keep my bald head warm. They just look really fun and cool. I get comments all the time from strangers about how cool my Bulbasaur hat is. I’ve got 4 different ones that I purchased from a con vendor between the last two MAGFests. Early this year though, I started making my own, including the 3 in the image above.

Making my own hats gives me more excuses to use the sewing machine I bought for last year’s cosplay project. It’s a fun challenge to learn the various aspects of design, patterning, and assembly. It’s fun to share (and wear!) what I’ve made with everyone else. Some of the skills overlap with new cosplay projects I’m starting. So really there’s lots of great reasons to do this (or so I tell myself).

This is by no means a side industry for me, but as I go along I’d like to share what I’ve made and learned. That will probably include a couple of tutorials, as well as the patterns I’ve created and digitized. When I was originally out searching for information on this topic, I came up surprisingly short-handed for making the particular kind of hat I wanted. So while there’s great resources out there from people clearly more expert than myself, I hope pulling this information into a common place will be helpful.

A particular kind of what?

Both years I’ve been at MAGFest, there’s been 2 or 3 vendors on the floor selling these fleece hats of Pokemon and other video game or movie characters. Since these are all hand-made items, each vendor has their own spin on how to design and build their hats. For example, all of the hats at one vendor follow a beanie template constructed from a single piece of fabric. This is the same kind of pattern that is easiest to find when looking for resources online.

The kind of hat I want to build is assembled from multiple pieces. An upper half made out of sections of “orange peel” and a lower half that could be a straight band or have ear flaps built in. Constructing a hat from multiple pieces creates more opportunity for sewing in features like ears, spines, tails, or other fun details.

Another difference is how details like eyes are created and added to hats. Some vendors cut out additional pieces of fleece or felt and sew them onto the hat, which I think gives a ragged look. An alternative is to cut out pieces of fuzzy vinyl heat transfers and iron them on. The details are sharp and there’s more opportunity for layering.

Perhaps the biggest reason I’m diving into all this is the vendor that used all those techniques I like, Athena’s Wink, has since closed their business. If I want hats like that, I may not be able to find them at the cons. I’ve got to make them myself. And I still have a few more I want for my personal use, like a Scyther and a Gumo.

Mannequin update

In my previous posting, I talked about my big fail trying to create a crude mannequin of my own head. Picking the wrong filling strategy (spray foam) quickly led to a total loss of the project. That’s super annoying, but the time investment to get to that point was only a couple hours, so I gave it another shot.

The masking tape process probably came together a bit better this time, leveraging my earlier experience. Combining the two haves on the other hand was trickier for reasons I don’t understand.

For filling, I tried to stick to the method in the video guide. I still didn’t have any stiff packaging Styrofoam, but I did have an old box full of packing peanuts. I haven’t seen packing peanuts actually used in shipping in years, so it’s probably not a common thing to have on hand. I had a few different kinds mixed together in my box. S-shaped peanuts. Figure-8 peanuts. Peanuts that look like beige cheesy poofs. The poofs are made of cellulose and dissolve in water, so they’d be a bad fit for this project. They were also way squishier than the others. I went with the S-peanuts exclusively since they were firmer and they broke up into small pieces very easily.

After filling a bowl with broken up peanuts, I mixed small batches with Elmer’s glue and then packed them into the head. With the cardboard supports in the way, it was difficult to direct the filling into all the spaces deeper in the head cavity. This only got worse after inserting 2 wooden support dowels halfway through. I ended up using about 4 mixing bowls worth of peanut bits before filling it to the top. After leaving the glue-soaked bits to cure over night, the head still felt really soft, and stiffer Styrofoam chunks would have probably been better in this case.

For the base, I didn’t have any more spent tape rolls lying around. I sacrificed my only one on the previous disaster. For a substitute, I cut two square pieces from 2×6 framing lumber, stacked them, and drilled two 3/4 inch holes. Stacking the two pieces gave me enough height to insert the wooden dowels without hitting the table below. The base and perimeter of the “neck” was glued down with hot glue. The drilled holes were wider than my dowels, so I injected hot glue into the remaining space to lock the dowels in place. It’s a nice stable base and I think it’s better than the tape roll method.

I followed the rest of the recipe to the letter. I coated the head in “paper towel gauze” with brushed diluted Elmer’s glue. This was also the place to make some minor corrections, like filling a wide dent in the forehead I created when I had it upside down for filling. Once the head was allowed to dry overnight, I painted over it with some ceiling paint I had on hand. I ended up with a lot of small cracking in the paint after it dried, so I probably applied the paint too thick. Though the paint was a bit old and I suspect not in great condition. The wet paint ended up softening the shell, but the end result is firm. I’m not planning to test that with any significant force, but it should be usable for projects.

The self-mannequin fail

I started attending MAGFest in 2017. For the two years I’ve gone, I’ve brought a cosplay with me. First was Gumo from Ori and the Blind Forest, which was a fun but time consuming project. Then there was Monster Kid from Undertale, which was a fun and much easier costume. With MAG 2018 behind us and the next one to look forward to, it’s time to start planning my next creation. (Spoilers, I want to try and do Scyther)

Beyond the very initial planning, which included partially assembling a paper craft, the first step is to create a reasonably good approximation of my own head. An auto-mannequin, if you will. After a little bit of looking, I decided to try this approach by Youtuber Dali DIY:

The gist of the process is you cover your face in aluminum foil, then fully cover it in layers of masking tape. The two halves are crafted separately and then rejoined after taking some measurements of your own head. By the way, if you need to measure your head, I found that a speed clamp works pretty well. It’s like a giant, less precise pair of calipers that you can clamp over your noggin, then measure with a ruler. Once you have your measurements, you cut some cardboard supports to glue inside and then recombine the halves. Once that’s good, you need to pack it with a filler. Dali uses a mixture of broken up Styrofoam bits and PVA (Elmer’s) glue. Pack the head, insert some support rods, mount it on something stable, and let it dry. The mannequin is further reinforced by covering it in strips of paper towel soaked in Elmer’s.

It’s rough and sloppy, but uses materials most of us have hanging around so it’s pretty cheap to try. And for making a bulky Pokemon head, rough should be good enough.

I started the process and it was going pretty well up through recombining the foil/tape halves with supports. Here’s a few pictures of that process.

But then I decided to change the script. I don’t have any styrofoam hanging around — I try to get rid of that stuff as fast as possible. And I don’t think I have enough glue either. And it looks like a pretty messy and time-consuming process to keep mixing up the foam and glue and stuff and pack that head mold. So what else do I have on hand that looks like a good candidate? Expanding spray foam!

In theory, I just shake up the can, spray it in the head, and let it expand to fill the cavity. All the excess foam can bubble and push its way out of the neck hole, and I’ll saw it off later.

Oh … oh god … what is going on … no … stop … aaaaaagh.

Well my first mistake was underestimating how much the foam would expand from its initial volume. It didn’t take long for the foam to break through the meager strips of tape covering my eye holes, oozing out and hardening in a foamy reenactment of the Chernobyl elephant’s foot. This went on for hours, and when it finally stopped and I cut off one of these eye pillars, the foam just started oozing again.

And this gets to the second and more fundamental mistake: expanding spray foam is not suitable for an enclosed cavity. Like a foil-lined head mold. Spray foam needs to react with moisture in air to expand and cure. With no source of moisture, it will remain in its frothy, volatile, semi-liquid state. Potentially forever. And after a day of letting this thing sit, the head readily caved in to even light pressure applied. The foam wasn’t curing, and now I have this nasty horror show of elephant-foot-face sitting on my counter.

If you’re working on a project and learning as you go, I don’t think it’s a bad thing to try and go off script. You might discover something cool. But maybe reconsider if you’re on a tight deadline. It might just melt down in front of you and you’ll have to start over from scratch.